This gives us one setup that contains the toolpaths for the 3 “even” WCS.

We currently use HSMWorks to program one setup of the part at G54 and then use the software to "copy" the toolpaths for WCS G56 and G58. The CAM program for the front (even) WCS are just copies of the G54 part, while the back (odd) WCS are essentially rotated with the signed movements of X & Y flipped. We currently setup the dual-station vises with the “front” location of each of the three vises as “even” (WCS G54, G56, and G58) and we designate the “back” locations as “odd” (WCS G55, G57 and G59). I am trying to figure out the workflow for setting up a simple part at WCS G54 (with all required toolpaths) and then copying / transforming / translating / rotating the setup to allow machining the same part in 3 dual-station vises (6 parts total). The top centre of the stock will be our work offset.I am seeking some help with SolidWorks Cam / Camworks. We will use a profile sketch of the part for the stock as it is provided as a blank. In this exercise, we will machine the top of the part below.

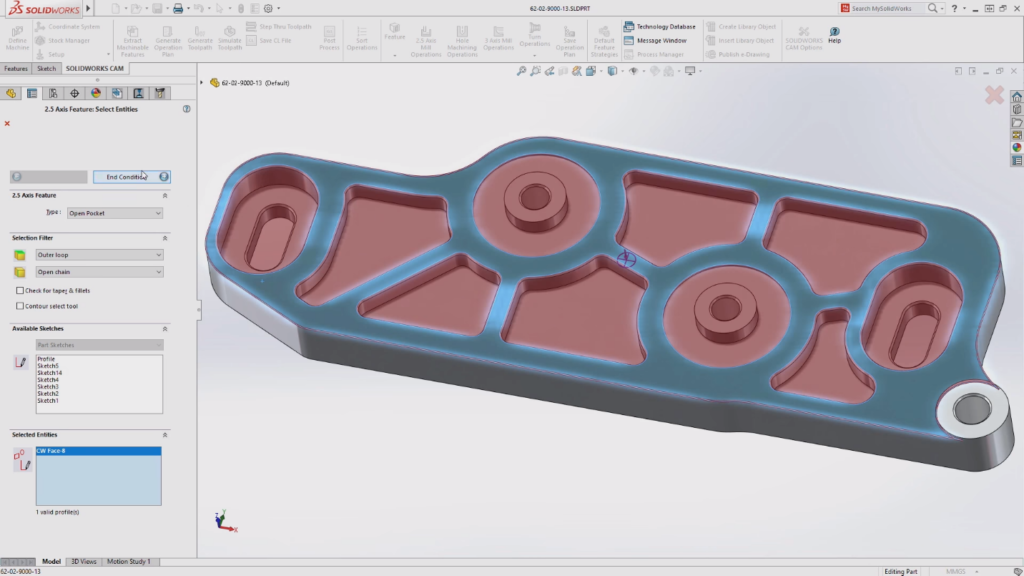

Learn more about 3D contouring toolpaths available in CAMWorks. This cycle can be used for finishing where excess material has already been cleared and supports single or multiple depths of cut. If a face/surface has even a small gradient, toolpath will not be generated. Toolpaths are only generated on completely flat areas.

Machine time can be a different story in these cases: For milling complex multi-surface features, SOLIDWORKS CAM is equipped with three tool paths to quickly and easily program most challenges.

0 kommentar(er)

0 kommentar(er)